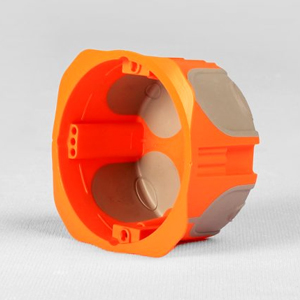

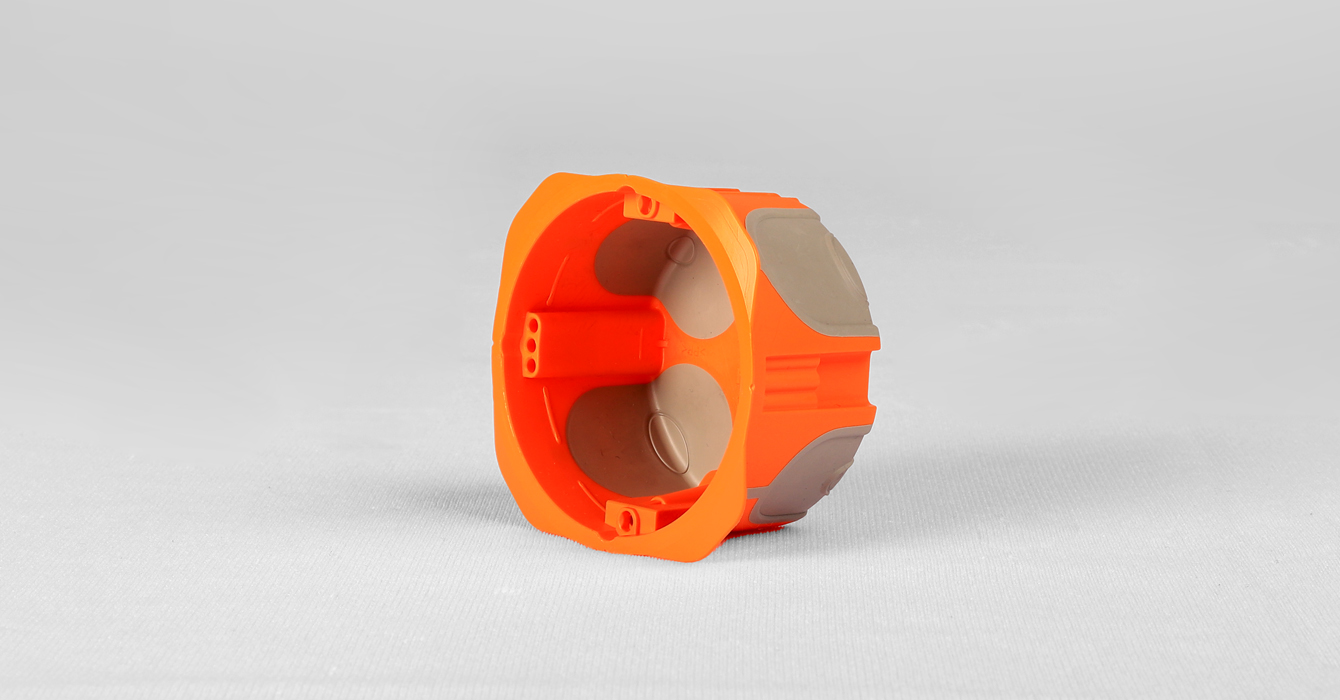

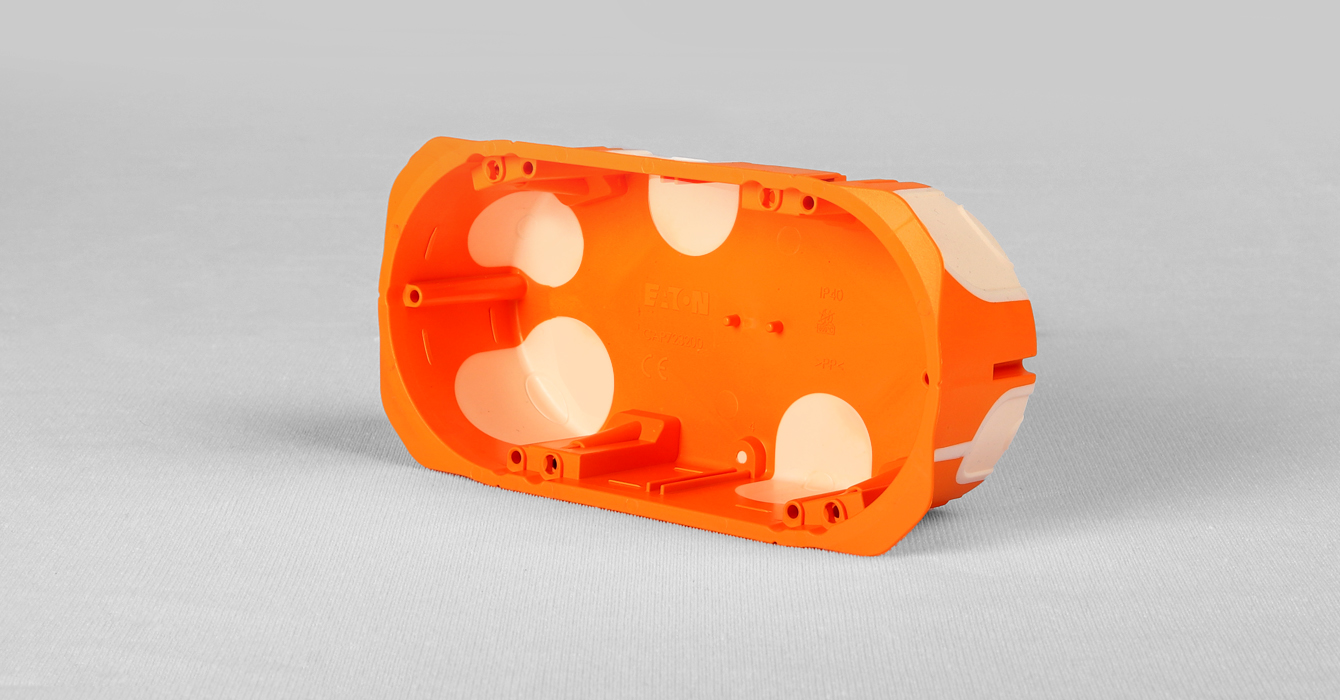

Bi-material

Plastic Injection

Cutting-Edge Technology

The plastic injection of bi-materials is at the source of our company project. Since 2007, we have took up challenges more and more complex: aesthetic parts, technical subassemblies and finished products with a weight from 10 grams to 4 kilograms approximatively, for a volume capacity from 500 to more than 20 million parts a year. We have a fleet of 18 injection moulding machines from 200 to 500 metric tons, with transfer moulds, rotary platens and with the core-back process. We use them according to the types of parts to be manufactured and the production volumes. We are also equipped with a double screw injection moulding machine which ensures us a perfect stability of the injection moulding process. Human skills and machinery show our comprehensive mastery in bi-injection.

We opt for the most suitable solutions to ensure the greatest possible sturdiness and the longest possible service life to finished products while reducing the assembly operations as much as possible.

Creation of

a Bi-material Product

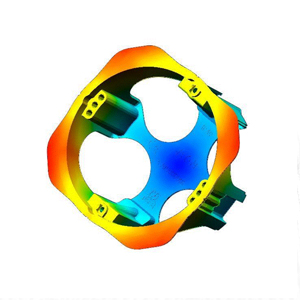

Feasibility Study and

Process Development

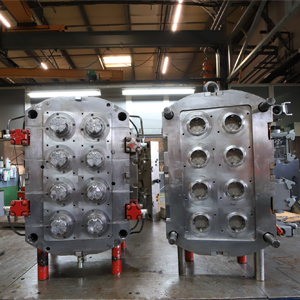

Mould Design

and Manufacturing

Part Manufacturing

by Injection Moulding Process

Finished Part