Design

Office

Intelligent Co-Developement

We create thorough technical specifications for each of your projects, in an innovative approach of co-development with our clients or on request. We make pre-study, study and monitoring of projects that are entrusted to us, whether they consist of assemblies or subassemblies, aesthetic or complex parts, etc. We use the current means of remote communication to keep an abiding link with your services.

The Skills, the Means…

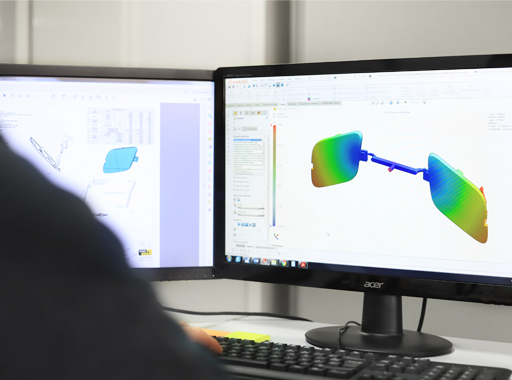

We have all the skills available in CAD in order to support you in designing, modifying and optimising your parts in preparation of their industrial output. In more specific terms, we are able to carry out the rheology studies concerning the deformations of materials and cooling calculations.

We have high-performance equipments:

• 3 CAD computer stations equipped with SolidWorks PREMIUM and Autocad INVENTOR

• 1 plotter for A0 format

• 1 data projector for the presentation of your projects

We can use all the following CAD formats (3D volume): Solidworks native files, CATIA native files, neutral files (.step), export files (.model and .exp).

From your specifications, your plan, your sketch or simply an idea, we have the means and the experience to give substance to your projects alongside the methods department.

…and the Methodology !

As a real user-interface between our manufacturing workshop and the design office, our methods department creates and supplies the tools needed for the production in order to enhance our productivity and the working conditions. This process also brings us analysis tools necessary for the Standard Cost-Benefit study, that is:

• Controlling the feasibility and the deployment of a product with the design office,

• Implementing the production means required (machines, operators, materials and equipments, etc),

• Defining time necessary for manufacturing, then setting and optimising times and production costs.

Thanks to a comprehensive mastery of manufacturing processes, our methods department carries out the complete development and manufacturing cycle for all your plastic parts with thoroughness and professionalism, from the prototype to be validated to mass-production.

1

Control of feasibility

and deployment of a product

2

Implementation

of production means

3

Definition

of production times

4